In episode 185 of the Disruptors for GOOD podcast, I speak with Morgan Bierschenk, co-founder of Geoship on revolutionizing homebuilding, through innovative and sustainable ceramic domes.

Listen on Apple Podcasts.

Listen on Spotify.

Listen to more Causeartist podcasts.

In a world grappling with pressing environmental and social challenges, the need for sustainable housing solutions has never been more critical.

The escalating costs of homebuilding pose a significant challenge in today’s world. Not only do construction and operation activities contribute to nearly 50% of global CO2 emissions, but they also fall victim to the destructive impacts of extreme weather events.

As our planet welcomes 3.6 billion additional inhabitants this century, the need for 2 billion new homes becomes a pressing matter.

However, this demand must be met while striving for net-zero carbon emissions. It is evident that homebuilding stands at the forefront of humanity’s most crucial issues in the coming decades.

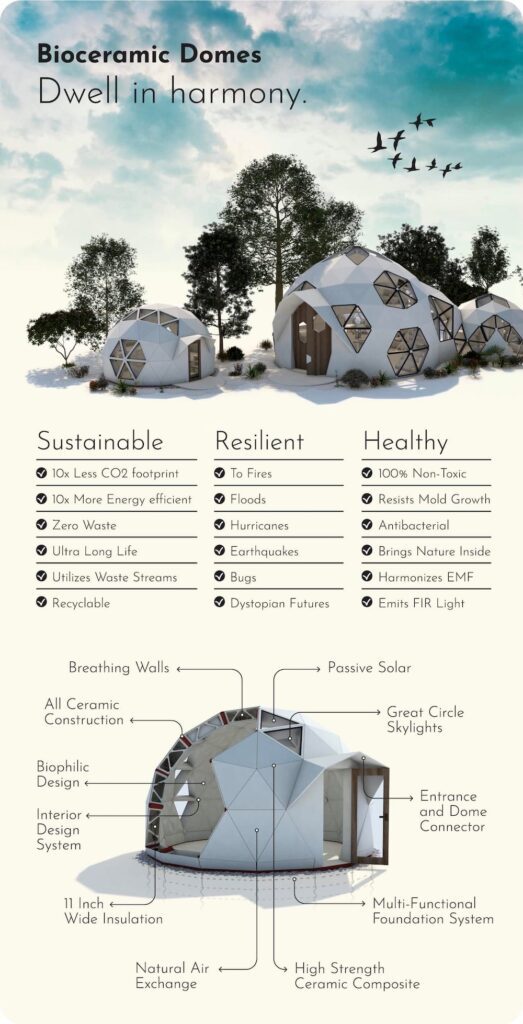

The company has emerged as a pioneer in the field of sustainable housing, offering a groundbreaking approach to building eco-friendly and affordable homes.

Through their unique geodesic dome design, Geoship aims to revolutionize the housing industry, providing resilient and regenerative homes that are energy-efficient and resistant to changing weather conditions.

By 2026, the company aims to manufacture 10,000 domes per year in a 200,000 square foot factory located in Nevada City, CA.

Their ultimate goal is to make the best home on Earth the most affordable home, and scale manufacturing to 1 million bioceramic domes per year by 2036!

Geoship’s Vision and Mission

Geoship is driven by a compelling vision and mission to create affordable, sustainable, and regenerative housing for all.

Founded by Morgan Bierschenk and Bas Kools, the companies mission is to combine ancient wisdom with cutting-edge technology to develop dome-shaped homes that are not only resilient but also contribute positively to the environment.

Inspired by the work of Buckminster Fuller, an acclaimed architect and inventor, Geoship integrates geodesic design principles with advancements in materials science and green building technology.

The Geoship Dome Homes: A Sustainable Solution

At the heart of Geoship’s innovation lies the geodesic dome design, which offers numerous advantages over traditional housing structures. Geoship’s domes consist of triangular facets that form a spherical shape, resulting in a structurally robust and stable home.

Their innovative approach involves creating precision-molded ceramic components that seamlessly fit together, akin to the assembly of LEGO blocks. This unique construction method enables the creation of residential dwellings that prioritize health, sustainability, and resilience.

The spherical shape also promotes efficient airflow, natural lighting, and temperature regulation, reducing energy consumption and reliance on artificial heating and cooling systems.

Affordability: Bridging the Gap

Geoship recognizes the urgent need for affordable housing and aims to bridge the gap between sustainability and affordability.

Traditional housing has become increasingly unaffordable for many, exacerbating social inequalities and limiting access to safe and sustainable shelter.

Our estimated go to market turnkey prices are $200-$250 a square foot (which is about 30% lower cost than conventional construction where Geoship is based in Northern California). At scale we’re aiming to sell turnkey homes for $80-$100 a square foot.

These prices encompass all-inclusive services, including delivery, permitting, installation, mechanical systems, interior finishings, and appliances.

Geoship anticipates that as manufacturing scales, their Bioceramic Domes will significantly reduce housing costs while simultaneously setting new standards for architectural excellence.

Regenerative Architecture: Holistic Sustainability

Geoship is committed to regenerative architecture, an approach that seeks to create buildings that actively contribute to environmental regeneration.

Geoship achieves this through the use of sustainable and non-toxic materials such as basalt fiber, which is highly durable and fire-resistant.

These materials are sourced responsibly and are recyclable, minimizing negative environmental impacts.

Geoship’s commitment to holistic sustainability extends beyond construction materials, encompassing regenerative practices such as permaculture, renewable energy generation, and water conservation.

Community Empowerment and Collaboration

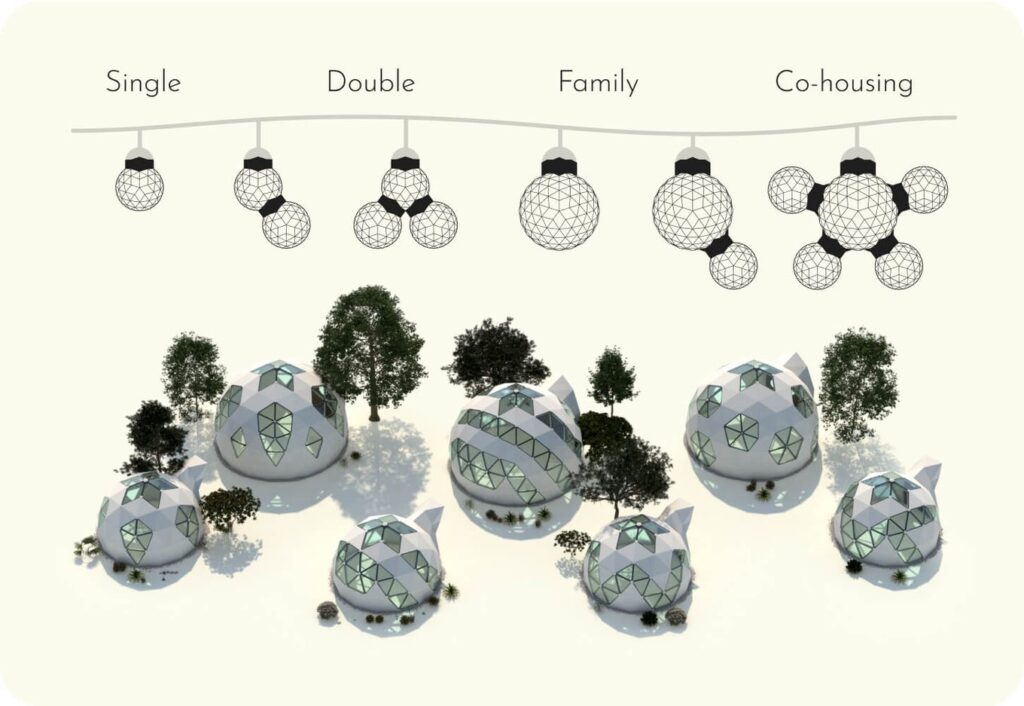

The company believes in the power of community and aims to create networks of like-minded individuals who share a vision for regenerative living.

By establishing Geoship communities, residents can come together to share resources, knowledge, and experiences, fostering a sense of belonging and collective empowerment.

These communities also serve as hubs for regenerative practices, promoting self-sufficiency and sustainability through activities like urban farming, renewable energy initiatives, and water conservation.

Q&A with Morgan Bierschenk, co-founder of Geoship

Q: What was the Lightbulb Moment / Origin Story of Geoship?

A: The thing to understand about Geoship is that it’s not a company in the current sense of what a company is. It’s a strategy for deep activism – planetary transformation.

Eight years ago, my brother and I started looking for ways to build a house efficiently. After delving down the rabbit hole of geodesic domes and bioceramic materials, we realized that this technology is so efficient and fundamental that it’s guaranteed to exist on a huge scale in the future. The only question is when?

I had exited the corporate world eight years before founding Geoship, so 16 years ago. During that time, I was vagabonding and sailing to push the boundaries of life — to have experiences that would help me become fit for service. I felt like the universe wanted me to be an artist with an instrument that didn’t exist yet. Something wanted to come through, but there was no way to express it.

Through extended meditation retreats and solo world travel, I contemplated, ‘What is my highest path of service to humanity’….not just for a weekend or a few months, but for eight years, that’s the thread I followed.

So, when I realized the true nature of ceramic dome technology, I asked,’Why should this come through me?’. The answer I’ve come to is that I have pure intention. I am crazy (but rational) and extremely determined to combine this fundamental housing technology with a business model and ownership structure that makes it a new tool, a new kind of instrument, for artists of the future to materialize their community visions.

That’s why we started a company instead of a non-profit. Technology companies are the most scalable vehicles for change. When ceramic domes are combined with a regenerative business model and decentralized ownership structure, you have something that’s never been able to exist before.

So that’s really what Geoship is, a new instrument for communities to express themselves and materialize the more beautiful world they imagine.

Q: What is Geoship’s Mission and Vision?

Earthshot: Manufacture 1 million domes per year by 2037. Our vision is to provide a village housing solution that reconnects human communities with the natural world.

Our Earthshot is to make the best home on Earth the most affordable and scale manufacturing to 1m bioceramic domes per year by 2037.*

Chemically Bonded Ceramics are to homebuilding what Lithium Ion batteries were to Electric Vehicles. They allow us to advance the art and create a new industry: Ceramic Homebuilding.

Development Timeline

With this funding round, we first develop a production-ready dome prototype. Then, we launch a village configurator to drive dome presales.

Next, we establish the first GeoRok blending plant as an early revenue stream. Finally, we aim to secure building permits for the first dome factory by 2024.

Geoship crosses the market chasm in 2024/2025. With the first 99 customer domes installed, enthusiastic early adopters telling our story, and a sales pipeline of over $1b, we begin ramping the first factory.

The company fuels growth through one or more Reg-A’s and an IPO.

Our ultimate product is not a dome but a highly automated dome factory. Geoship begins replicating factories, scaling to 1m domes per year from 2028 to 2037.

Rather than building a few 100-acre Gigafactories, we launch many 2-10 acre micro-factories. Our development timeline may seem long, but it’s slightly faster than Tesla Motors.

Open the ‘Etsy’ of Natural Building

Bioceramic Domes create the opportunity for a new ecosystem of products and services. Geoship launches a market network to support the growing cottage industry around healthy and natural building.

Artisans, furniture makers, cabinet makers, dome installers, natural builders, developers, architects, permaculturists, interior designers, and complimentary product/service providers all become members of the Geoship market network.

Decentralize and Gamify Homebuilding

Today, housing developments are built by speculative developers and banks, then sold to homebuyers.

Geoship offers a suite of Web3 tools for communities to 1) align around a common purpose, 2) generate a shared vision, 3) support each other with collective action, 4) pool resources, 5) crowdfund land, and 6) participate in building the regenerative village they’ve imagined.

What Tools Do You Use to Run Your Company / Organization (Mailchimp, Shopify, Webflow, Slack, Salesforce…..)?

Interview Transcript

00:10

Host: Well, thank you so much, Morgan, for joining me today. Super excited to chat about the journey of GeoShip, its mission and vision. I’ve followed you guys since inception and love to see the maturation and innovation that’s gone into this idea. It’s going to change a lot of lives, I think. Before we get into GeoShip, talk a little bit about your journey and what was the catalyst for taking this on.

00:35

Morgan: My first real job out of university was with Intel Corporation when I was 20. After about four years, I saved up 100 grand and decided I was done. I started traveling, spending about two years in Asia and India. Then I came back and restored a classic wooden sailboat in a barn for a year, lived aboard for about six years, optimizing my time for meditation and learning, trying to understand my highest service to humanity.

I refused to take another job just for money. This led me to various organizations, including knocking on the door of Ellingham Hall where Julian Assange was under house arrest in 2011, wanting to help with the Freedom of Information movement. This got me to Iceland, working with the Icelandic Modern Media Initiative and the Pirate Party.

During this time, I restored the sailboat as an alternative to building a small cabin in nature. After Iceland, I came home and started building a house with my brother, who has a background in CNC mold-making for boats. We started thinking about the most efficient way to build a house, looking into physics first principles, and that’s how we landed on ceramic domes.

04:38

Host: Segueing from the idea, was it initially just for yourself like with the boat, or did you always plan on building a company?

05:05

Morgan: We started on Whidbey Island outside of Seattle, initially focused on small scale artist and community structures. But as we delved into the material science and technology, we realized this could be a global solution. We started working full-time on GeoShip in 2015. I sold my home, took all my money, and started bootstrapping. Our first angel investor let us squat at a farmhouse with a barn where we developed the material science. It was a long learning and development process, but now we’re super on time and accelerating.

06:34

Host: It’s hard to convey in audio, but when someone asks you what a GeoShip is, how do you describe it? Has it turned out cooler than you imagined?

07:13

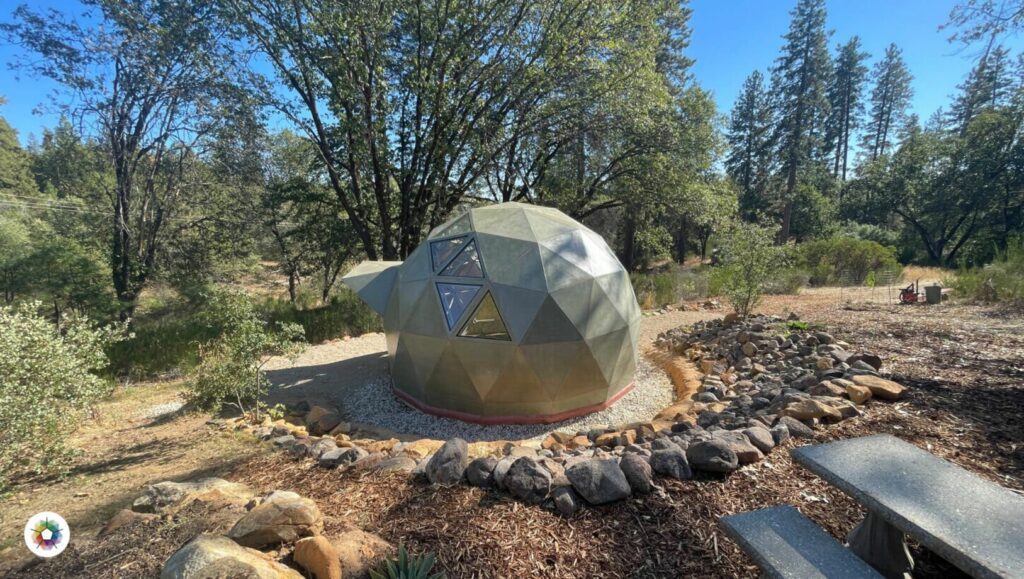

Morgan: It’s way more exciting every week. From a manufacturing perspective, the geodesic dome is efficient because each component weighs no more than 30 pounds, so no heavy equipment is needed on site. The build process is like a placemaking festival with no cutting or measuring. The dome can be repaired and resurfaced with the same material it’s made of, reducing the carbon footprint of housing by 93%. It’s designed for a 500-year life, with materials that don’t rot, mold, burn, or attract insects. The raw minerals can come from various waste streams, making it even more sustainable.

10:01

Host: What about weather resistance, like extreme heat, hurricanes, or snowfall?

10:32

Morgan: We haven’t done advanced testing yet, but the material can have the flexural strength of steel, making the geodesic dome aerodynamic and resilient to hurricanes. It’s also earthquake-resistant due to its integral structure. The material is refractory and fire-resistant, and it can be submerged in water for a decade and still dry out stronger.

11:29

Host: It almost looks like a cybertruck as a home. Let’s talk about the potential for affordable housing. How can GeoShip fit into different economic scales and geographic locations?

12:39

Morgan: In the future, not everyone will live in boxes, and communities will populate the land from the cloud. Instead of developers and banks building homes, communities will come together in digital spaces, participating in the design of their villages. This includes local currencies and decision-making technologies. We work with organizations like Regen Villages to integrate village designs with local ecology and optimize for regenerative living.

14:34

Host: Can you talk about your journey as a founder, starting from scratch and building this company?

15:14

Morgan: It’s hard to give advice because it’s different for everyone. I was determined to do something impactful, not just for profit or impact but to steward a vision. I had strong conviction that this was the path, and I wouldn’t stop no matter what. It’s been my life’s work, and I think many founders start smaller companies as stepping stones. I dove headfirst into a big project and learned along the way.

17:02

Host: Where are you now in the process? Are domes being made for the public yet?

17:20

Morgan: We’re in Nevada City, California, and just completed the first functional prototype. We’re raising another round of capital to start pilot production, aiming for a seed round to finish the deep R&D. Next year, we’ll raise a bigger round to build the first manufacturing facility for volume production. Initially, we’ll produce one to three domes a month, developing the manufacturing technology, then scale up to 10,000 domes a year.

19:13

Host: What about pricing? How do you see costs evolving over time?

19:44

Morgan: Initially, we’re looking at about $200 to $250 per square foot. In 10 years, we aim to bring that down to $75 per square foot in the US. Our goal is to provide homes that are 2.5x median income everywhere. We’re also exploring government grants and potentially DOE loans to support affordable housing and carbon reduction.

21:04

Host: Have there been conversations with government officials about subsidizing this new way of building houses?

21:04

Morgan: Definitely. The Inflation Reduction Act provides substantial funding for affordable housing and carbon reduction. We’re pursuing government grants and loans to build our first factory. We’ve also had discussions with Tony Hsieh, the founder of Zappos, who challenged us to create a for-profit business model that could transcend homelessness across America. Our model involves selling domes at regular price and donating one for every few sold to transitional villages.

23:29

Host: The modular aspect is fascinating. Can these domes be expanded and connected?

23:56

Morgan: Totally. The dome is a fundamental shape, but our technology can be used for other non-rectilinear shapes. It’s versatile and can be adapted for various building structures.

24:15

Host: Do you collaborate with other companies in the space, like those working on 3D-printed homes?

25:03

Morgan: 3D printing is often seen as the future of housing, but it has limitations. Our technology allows for building in more difficult locations without heavy equipment. While we’re focused on our minimum viable product, our technology fits well with 3D printing and other onsite applications.

26:34

Host: You’re doing another crowdfunding round on Republic. What will this round fund?

26:58

Morgan: Sales haven’t been a problem; we have a $50 million sales pipeline with no marketing. This round will help us iterate on the prototype, develop the manufacturing technology, and start pilot production, producing a few domes a month.

27:32

Host: What are your goals for the next five years?

27:52

Morgan: In five years, we aim to have an autonomous factory producing around 10,000 homes a year and the first village completed, likely in Nevada City. We also envision hundreds of digital villages designed by communities, potentially forming networks and seeking diplomatic recognition. It’s about creating thriving communities with strong relationships with their ecology and each other.

31:00

Host: Thank you so much, Morgan. What you and your team have accomplished is incredible. Best of luck to you for the future.

Morgan: Thank you so much, Grant.