unspun, the leader in 3D weaving technology, has successfully raised $32 million in an oversubscribed Series B funding round.

The funding was lead by DCVC, with additional support from Lowercarbon Capital, E12, Decathlon, and SOSV.

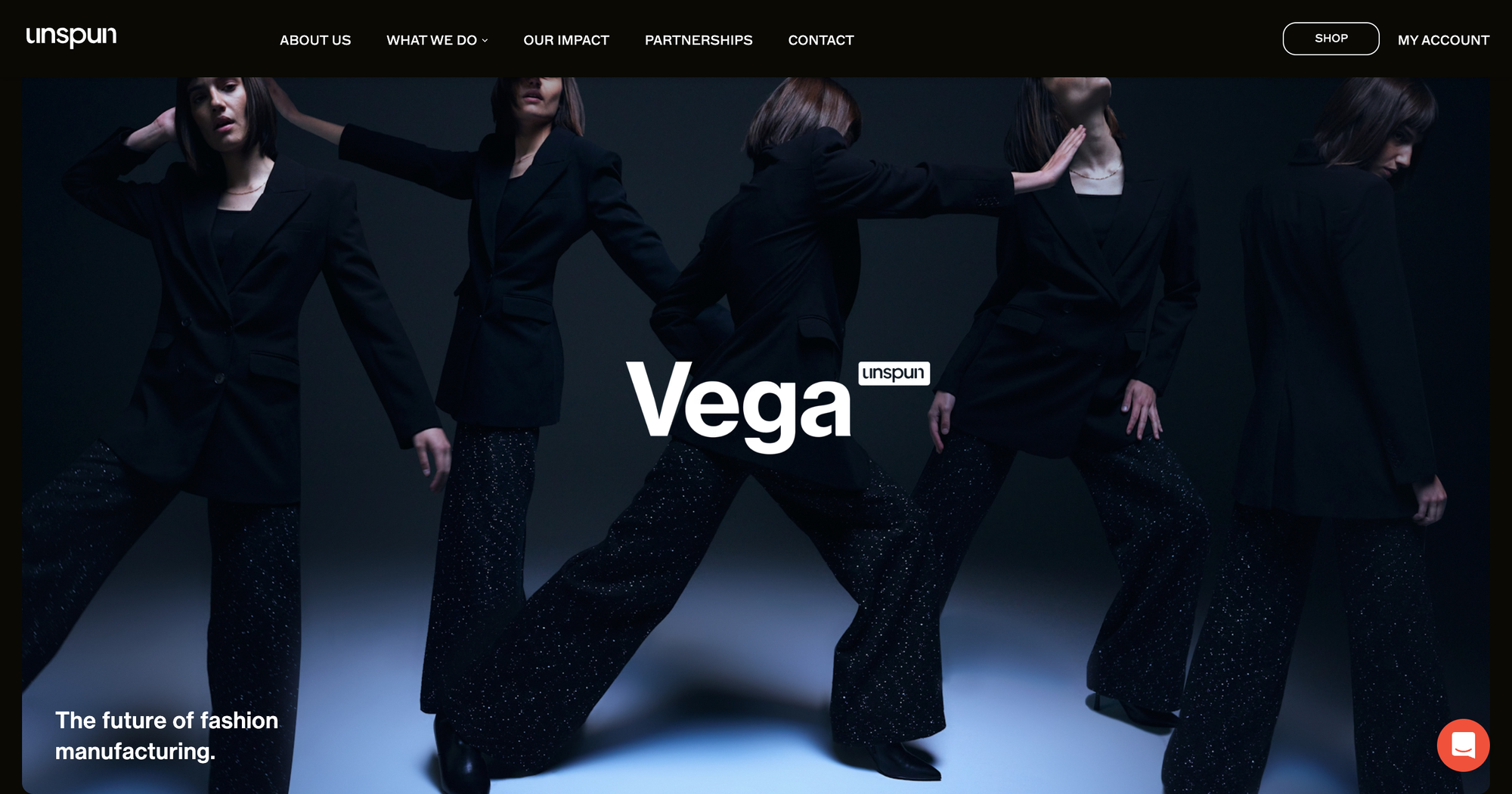

This investment will propel unspun’s cutting-edge Vega™ technology, enabling the company to revolutionize fashion supply chains in Europe and North America.

About unspun

unspun is a US-founded fashion-tech B-corp committed to reducing global carbon emissions by 1%. The company’s flagship technology, Vega™, weaves clothes from yarn in minutes, simplifying fashion supply chains into vertical operations.

This 3D weaving and digital fit technology is the fastest, cleanest, and most cost-competitive way to manufacture woven apparel.

unspun partners with brands and manufacturers dedicated to streamlining and decarbonizing fashion supply chains through automated, localized, and low-impact production.

The Vega™ Technology: A Revolution in Apparel Manufacturing

At the heart of unspun’s innovation is Vega™, the world’s first 3D weaving technology designed specifically for apparel.

This technology takes thousands of yarns and weaves them into garments in mere minutes, facilitating nearly zero-waste, on-demand manufacturing.

The implications for the apparel market, which represents 57% of the total fashion industry, are profound. Vega™ allows for scalable on-demand or low-inventory production, drastically shortening supply chains and lead times.

Benefits of 3D Weaving Technology

unspun’s Vega™ technology offers several significant advantages:

• Speed and Efficiency: Vega™ technology is four times faster than traditional manufacturing methods.

• Environmental Impact: The technology reduces emissions by 53%, energy demand by 49%, and water consumption by 39%. Additionally, it generates less than 3% cut waste compared to the industry average of 15%.

• Local Production: Brands and manufacturers can integrate Vega™ machines into existing supply chains for localized and automated production, leading to a more responsive and agile supply chain.

Scaling Operations and Partnerships

With the new funding, unspun is set to scale its operations by licensing its technology to established manufacturing partners in Europe and North America.

The company has already signed multi-year agreements with major retailers like Walmart to deploy Vega™ machines for localized production.

This growing demand highlights the industry’s shift towards sustainable and efficient manufacturing solutions amid increasing regulatory pressure and consumer demand for supply chain transparency.

Addressing Overproduction and Circular Supply Chains

unspun’s approach comes at a critical time, with record levels of unsold goods circulating in the fashion industry.

By partnering with brands and manufacturers committed to decarbonizing their supply chains, unspun aims to address overproduction issues.

The company is also developing circular supply chain applications, creating products and manufacturing techniques that allow garments to be unspun back into yarns and re-woven into new items.

Vision and Future Developments

The potential of Vega™ technology extends beyond current applications. While the current generation of Vega™ machines focuses on high-quality outputs for bottoms, bags, and hats, future iterations will expand into performance categories, outerwear, shoes, tops, and dresses.

The versatility of Vega™ allows it to create woven garments using almost any yarn, opening endless possibilities for the fashion industry.

Recent Collaborations and Future Plans

The company recently partnered with Walmart to localize parts of the retailer’s manufacturing, enhancing supply chain traceability in North America.

Additionally, unspun collaborated with fashion label Eckhaus Latta to introduce the first-ever 3D woven collection at New York Fashion Week.

These products are now available online and in stores globally. unspun also played a crucial role in launching designer Ana Kraš’ lifestyle brand, Teget.